BLOCK PBH 41

Application

Quick-installation element for efficiently mounting pipe clamps and other components to all Channels of the 41 series, suitable for double channels also.

Time saving due to pre-assembled block - replaces 2 individual parts.

Due to the force of the integrated spring, self-supporting if used for vertical channels; can however still be easily moved along the channel by hand.

To be combined with Pressix Rods PNS, grub screws, bolts and other threaded elements.

Scope of delivery

Pre-assembled.

Installation

Insert the Block into the channel; by turning the Holding Bracket by 90° to the right, the Channel Nut locks into the stop position; then tighten nut or other connecting part with torsional moment (M) of max. 40 Nm - the job is done!

Technical Data

Material: Steel, electro-galvanised.

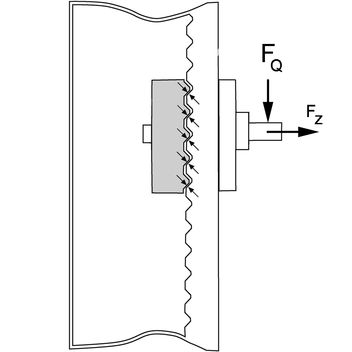

| Min. material thickness Channel 41 [mm] | FZ * [kN] | FQ * [kN] |

|---|---|---|

| 1.5 | 4.7 | 2.0 |

| 2.0 | 5.8 | 2.0 |

| ≥ 2.5 | 5.8 | 2.0 |

Perm. load FZ * under stress of fire

| Min. material thickness Channel 41 [mm] | FWD 30 [N] | FWD 60 [N] | FWD 90 [N] | FWD 120 [N] |

|---|---|---|---|---|

| 2.0 | ≤ 850 | ≤ 430 | ≤ 250 | |

| ≥ 2.5 | ≤ 1000 | ≤ 540 | ≤ 350 | ≤ 250 |

FZ = max. permissible tensile load

FQ = max. permissible lateral force against displacing

* The load capacity of the connecting parts used is to be considered. This applies particularly under stress of fire.

| Code | Name | Weight | Number of pieces | ||

|---|---|---|---|---|---|

| 198988 | PBH41 M 8 | 0.05 | 50 | Information request | |

| 198995 | PBH41 M10 | 0.05 | 50 | Information request | |

| 199008 | PBH41 M12 | 0.05 | 50 | Information request |