FLEXIBLE METAL TUBE

Application

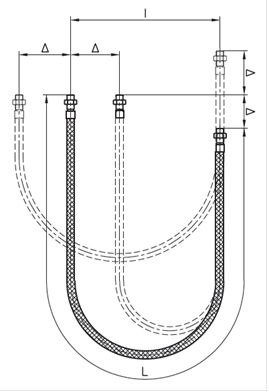

This configuration is generally used near structural earthqauke proof joint, in particular when it is necessary to prevent pipes break in case of earthquake.

This system allows to absorb all direction movements.

Technical data

The standard material used in manufacturing the tube is stainless steel ASTM A 240 Type 321. On request, stainless steel ASTM A 240 Type 316L is also available. The braid is produced in stainless steel ASTM A 240 Type 304.

The fl exible metal tubes can be used with operating temperatures from -270°C up to +600°C. Above 50°C, the pressure reduction factor CP based on the temperature must be taken into account. Possible pivoting flanges in PN16 steel.

Nominal Pressure PN: maximum allowable pressure at room temperature. Test Pressure PP: must not exceed 1.5 times the nominal pressure PN. Bursting pressure PS: is at least 4 times greater than the nominal pressure PN.

| DN | Dinamic bending radius [mm] | L [mm] | ±Δ [mm] | I [mm] |

|---|---|---|---|---|

| 1/2" | 140 | 1000 | 120 | 400 |

| 140 | 1500 | 240 | 520 | |

| 140 | 2000 | 360 | 640 | |

| 3/4" | 170 | 1000 | 90 | 430 |

| 170 | 1500 | 210 | 550 | |

| 170 | 2000 | 330 | 670 | |

| 1" | 190 | 1000 | 70 | 450 |

| 190 | 1500 | 190 | 570 | |

| 190 | 2000 | 310 | 690 | |

| 1"-1/4 | 260 | 1200 | 70 | 590 |

| 260 | 1700 | 190 | 710 | |

| 260 | 2200 | 310 | 830 | |

| 1"-1/2 | 300 | 1500 | 110 | 710 |

| 300 | 2000 | 230 | 830 | |

| 300 | 2500 | 350 | 950 | |

| 2" | 320 | 1500 | 90 | 730 |

| 320 | 2000 | 210 | 850 | |

| 320 | 2500 | 330 | 970 | |

| 2"-1/2 | 460 | 2000 | 100 | 1020 |

| 460 | 2500 | 220 | 1140 | |

| 460 | 3000 | 340 | 1260 | |

| 3" | 1500 | |||

| 4" | 1500 | |||

| 5" | 1500 | |||

| 6" | 1500 |

Note:

The dynamic bending radius indicates the minimum curvature at room temperature and nominal pressure for several repeated movements. The static bending radius indicates the minimum curvature at room temperature and nominal pressure for one single movement.

Warnings

- Avoid damaging the tubes (abrasions, painting, welding splatters, deposits of dust or resin between the corrugations, etc.);

- Avoid twisting the tubes;

- Do not exceed the allowable bending radius;

- Keep the movements in a single plane only.

| Code | Name | Weight | Number of pieces | ||

|---|---|---|---|---|---|

| TFAA021100 | 21,3 mm ½'' L=1000 mm | 1.20 | 1 | Information request | |

| TFAA021150 | 21,3 mm ½'' L=1500 mm | 1.20 | 1 | Information request | |

| TFAA021200 | 21,3 mm ½'' L=2000 mm | 1.20 | 1 | Information request | |

| TFAA027100 | 27,9 mm ¾'' L=1000 mm | 1.76 | 1 | Information request | |

| TFAA027150 | 27,9 mm ¾'' L=1500 mm | 1.76 | 1 | Information request | |

| TFAA027200 | 27,9 mm ¾'' L=2000 mm | 1.76 | 1 | Information request | |

| TFAA034100 | 33,7 mm 1'' L=1000 mm | 2.51 | 1 | Information request | |

| TFAA034150 | 33,7 mm 1'' L=1500 mm | 2.51 | 1 | Information request | |

| TFAA034200 | 33,7 mm 1'' L=2000 mm | 2.51 | 1 | Information request | |

| TFAA042120 | 42,4 mm 1''¼ L=1200 mm | 3.38 | 1 | Information request | |

| TFAA042170 | 42,4 mm 1''¼ L=1700 mm | 3.38 | 1 | Information request | |

| TFAA042220 | 42,4 mm 1''¼ L=2200 mm | 3.38 | 1 | Information request | |

| TFAA048150 | 48,3 mm 1''½ L=1500 mm | 3.69 | 1 | Information request | |

| TFAA048200 | 48,3 mm 1''½ L=2000 mm | 3.69 | 1 | Information request | |

| TFAA048250 | 48,3 mm 1''½ L=2500 mm | 3.69 | 1 | Information request | |

| TFAA060150 | 60,3 mm 2'' L=1500 mm | 5.18 | 1 | Information request | |

| TFAA060200 | 60,3 mm 2'' L=2000 mm | 5.18 | 1 | Information request | |

| TFAA060250 | 60,3 mm 2'' L=2500 mm | 5.18 | 1 | Information request | |

| TFAA076200 | 76,1 mm 2''½ L=2000 mm | 6.60 | 1 | Information request | |

| TFAA076250 | 76,1 mm 2''½ L=2500 mm | 6.60 | 1 | Information request | |

| TFAA076300 | 76,1 mm 2''½ L=3000 mm | 6.60 | 1 | Information request | |

| TFFA089150 | 7 | 1 | Information request | ||

| TFFA114150 | 12 | 1 | Information request | ||

| TFFA139150 | 17 | 1 | Information request | ||

| TFFA168150 | 20 | 1 | Information request |